For years, a manufacturer used a simple vibrating feeder to charge a bulk blend into the press die cavity. The feeder would retract, and the human operator would step forward to visually check the die fill and manually level the "pile". Although recent changes to the press interlocks had made the operation safe enough, it was still undesirable to have an operator at the opening of a huge press, and the human intervention slowed the press cycle.

Applicon was asked to design a press charging system that would fill the die cavity uniformly, without operator intervention, to improve both safety and cycle time. We were initially directed to place the charging system in front of the press. That location was obvious because it was easy; the front of the press was quite open. Yet any charging system (old or new), placed in front, blocks access for inspection and die changes, and complicates the ejection and handling of the finished block.

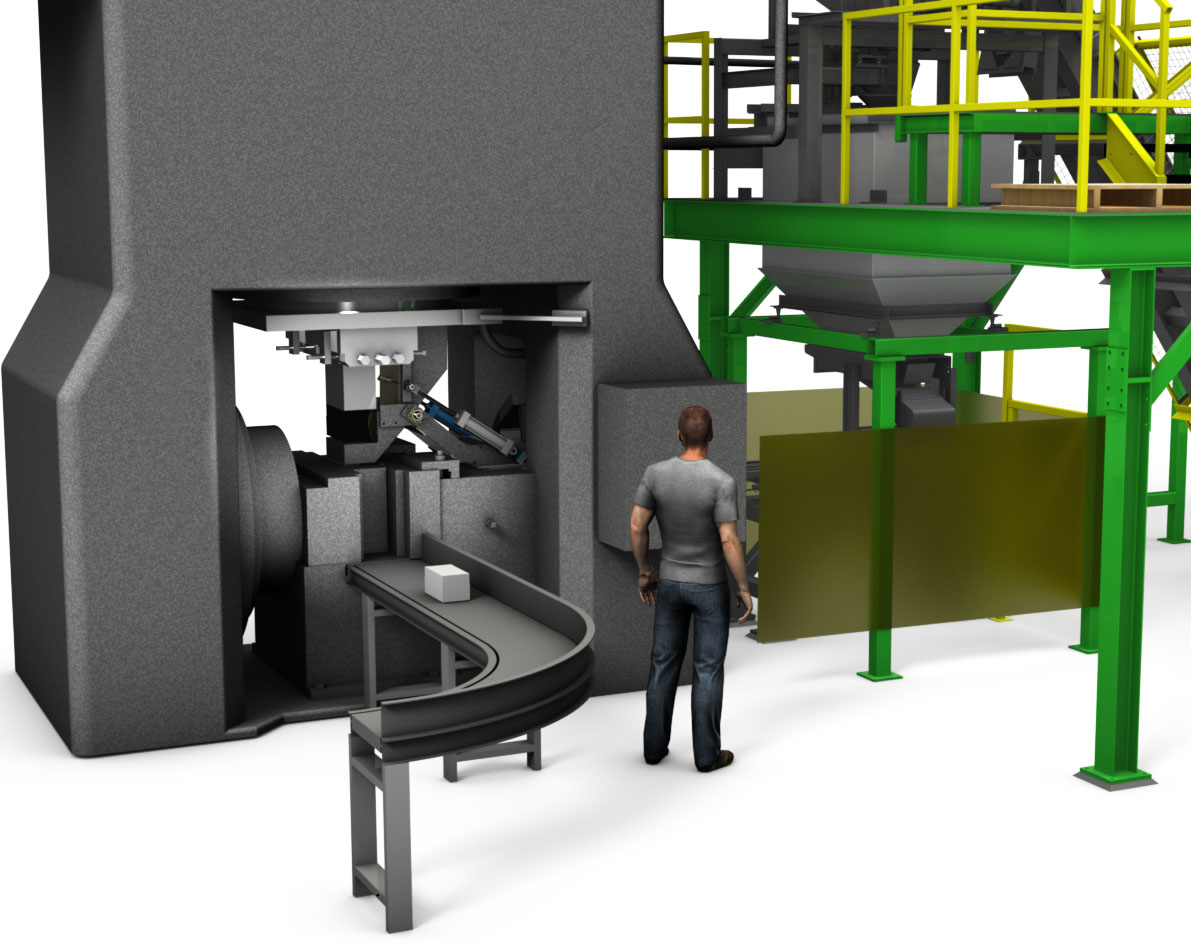

After much consideration and modeling of the press, Applicon designed and built a charging system to utilize a narrow side "window" of the press. The new low profile charger, with telescopic ways, extends through that press window and dumps the batch in a matter of seconds. This side access also insures even filling of the rectangular die cavity, so that the punch is evenly loaded on the compression stroke. The front of the press remains completely open, allowing the operator to observe, but not participate in the cavity filling. Dual palm buttons allow the operator to intercede if necessary, and a safety light curtain provides failsafe backup against entry into the danger zone.

The Press Charger also eliminates the need for the operator to manually apply dry die lubricant. An integral supply system meters a dose of powder into the die, prior to dumping the batch. See Moly Injection.

| This system included • Check weigh scale • Low profile, telescopic charger • Acceleration and decel control • Safety light barrier • Press ram position sensing |