Applicon makes an entire range of equipment for dumping bags, splitting or slitting bags, pouches and sacks. From all manual or semi- manual, to fully automated extraction systems, Applicon components are designed to remove all of the product from kraft bags, kraft with plastic liner, or all plastic bags products from 25, 50, 80 lb. bags.

Manual opening systems

Our standard bag break station is 38” wide inside. This accommodates a long bag, and still leaves room for the operator to grasp the ends of the bag. The front bag ledge is full width, is smooth, and is slightly raised from the dump grate. This allows the bag to be reoriented and slide forward, half onto the bag grate. Thus the operator exerts little effort manipulating the bag. The ergonomic design allows the operator to stand erect to cut and empty the bag. This protects the lumbar spine and preserves the stamina of the operator.

Removable Bag Grate

The removable bag grate is customized to each application, but the Applicon standard is a stainless wide mesh screen atop support bars. This provides a smooth surface for further sliding or rolling the bag without snagging or tearing bits of the bag material.

Dust Control

During bag opening, dust containment is crucial for meeting operator exposure limits. Because the dust is also the ingredient, Applicon has multiple designs to minimize fugitive emissions while also minimizing loss of product to dust collection. When our dump stations are vented to a central dust collector, Applicon designs the upper body of the collector for high volume, low velocity airflow to allow most of the product to settle and fall to the product hopper. For best retention of ingredient, Applicon DC bag dumps have integral filter bags and reverse pulse cleaning, so 100% of the bagged ingredient is delivered to the process.

Difficult Ingredients

Applicon builds a wide range of lower bodies and hoppers to receive the de-bagged ingredients. The least expensive and largest volume hoppers are rectangular with pyramidal bottom. We build pyramidal hoppers with formed corners to insure a smooth radius that allows product to slide freely. For slightly more difficult ingredients, the pyramid will transition smoothly to a round outlet. For cohesive powders, we offer round body conical bottom hoppers which may be further enhanced by any number of discharge components and flow aids for dependable extraction and metering. See Applicon feeding & dispensing

|

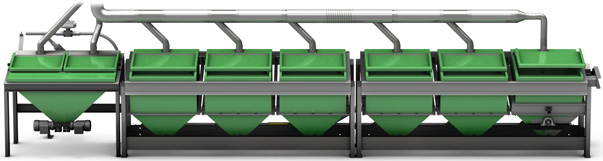

Minor and Micro Ingredient Station

The dump stations pictured above are for minor and micro ingredients each include a chisel bottom and auger feeder. A slot opening in the cover door allows the operator to quickly see if the hopper needs to be refilled. Lifting the door automatically opens that station to the dust collection system.

|

Dump These • Bags of any type • Cartons or Boxes • Pail or Fiber Drum • Steel Drum • Saggars or Pans Infeed Types • Manual Placement • Drum/box Tilter • Vacuum Bag Lifter Throughput Waste Disposal • Manual removal • Manual insertion to compactor Product Discharge • Integral bar grate • Vibrated bar grate • Integral sifter • Screw feeder or conveyor • Vacuum pickup or airlock • Fill head to portable bins Dust Control • Integral collection & dust return • Or, exhaust to plant collector |

|