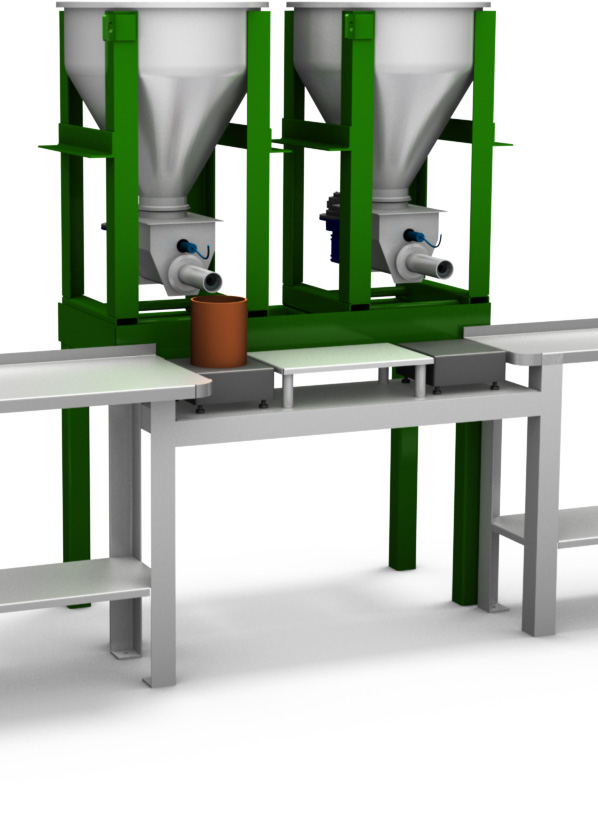

Applicon builds systems for weigh filling powders, granules and blends, into bag, box, bucket, tote, tray, octabin, bulk box, or gaylord box. Systems can be manual, or semi-manual, semi-automatic, or fully automatic, and can include:

• Portable bins or stationary product hoppers

• Screw feeders, twin screw feeders, vibratory or oscillating feeders, or combination auger/vibratory.

• Single or multiple net weigh scale hoppers operating, with blending effected in transit between the scales and the container.

• Multi-ingredient tumble blending immediately above filling.

• Bottom up filling, to either to limit particle segregation or reduce fluffing / fluidization of powders.

• Vertical auger filling, also used for filling from the bottom up, and

• Vibrated filling, to de-aerate or densify in the container. This works best when used with a pre-weighed batch, but can also be done with a gross weigh scale, at a slower rate.

• Digital load cells for very high scale resolution.

• Empty container queuing and conveying.

• Manual or automated liner insertion station

• Filled container de-aerating, lidding, closing, or sealing.

• Filled container handling and accumulation.

• Manual manipulator, automated pick & place, or robotic palletizing.