An international beverage manufacturer was manually fulfilling batches of twelve minor and micro ingredients. Because the flavors are temperature sensitive, the ingredients and the weighing were in a cold room. Operators would go from a warm plant into this chilly room, and proceed to make batches…..quickly !

Each formula or recipe card could require six to twelve ingredients. The operator would bring the packages to either of two floor scales, and scoop or pour from each bag into a portable bin. When the bin was filled, it was tagged and rolled aside. Multiple bins were filled, parked, and marked for the production tank.

There were many, many portable bins, and many trips into the cold room, to move the bins into position to transfer the batch to the production tanks.

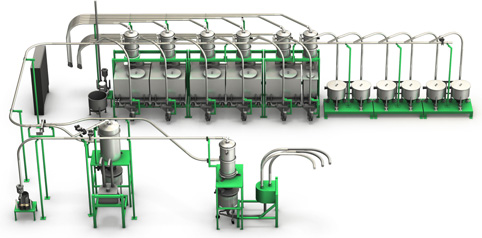

Applicon designed a sanitary storage and batching system to operate inside of the cold room, allowing the operator to refill the storage hoppers only once per shift, and then exit the room. All other functions are automatic.

Six large hoppers for minor ingredients are filled pneumatically; six smaller hoppers are filled directly. All hoppers weighed in lieu of level sensing.

Upon demand and following the downloaded recipe, the system sequentially meters each ingredient into a vacuum conveying system, where it is transported and weighed at either of two scales. Minors and micros are weighed together in the same high accuracy scale. The tolerance even of the micros is very good, through the use of a longer "dribble" period and line purging.

The completed batch is discharged to a holding bin, releasing the scale to make another batch. When the target production tank calls for the batch, it is pneumatically educted and blown to the destination. The system can have four batches ready or in process, always ahead of the 45 batches per day that are required.

| This system included: • Six bulk hoppers for minors • Six micro hoppers • Sanitary screw feeders • Vacuum batching system |