|

FIBC Dispenser • Hoist • Operator Handbox • 11 cu. ft. 304 Stainless |

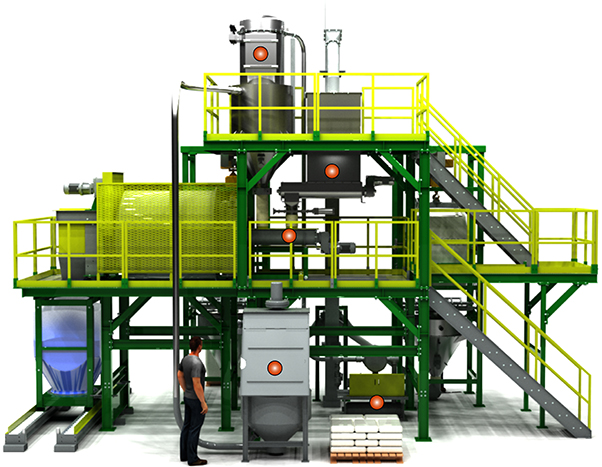

This system to produce designer plant nutrients was designed to batch, blend and package up to 9 tons per hour of product. Major ingredients come from FIBC bulk bags, or eventually from silos or by front loader from bulk piles. Minor ingredients are dumped from bags, or manually weighed from pails and small bags.

The system is designed for minimal cross contamination between batches, and minimum labor for handling.

Bulk Bag Dispenser

Applicon StHd-2 bulk bag dispensers with electric hoists allow the operator to lift and place a bag efficiently, safely and more accurately than a high mast forklift. This allows the swift exchange of the emptied bag for a full bag, keeping the supply on hand and ready to refill the scale bin. Actuated massage tables flex the bottom of the FIBC to break product that is bridged, and keep product moving through the bag spout.

The handbox allows the sack spout to be untied and then opened without risk to the operator. A vent port tied to the dust collector keeps the handbox and hopper under a slight vacuum, eliminating dust emissions as the hopper is refilled. This dust control also works when the FIBC is empty. Simply lower the hoist to collapse the bag, then remove the spout from the handbox.

Each hopper holds 11 cu.ft. ( 300 l) and suspends from isolators. When the hopper vibrator is ON, all of the energy is transmitted to the stored ingredient. The dispenser frame and even the conveyor below, are isolated from vibration.

Inclined Screw

Each Applicon inclined screw feeder is isolated from the feed hopper above by a flex sleeve, keeping the hopper outlet to vibrate unconstrained. Equipped with VFD, the feeder delivers up to 1,200 lb/minute until the dribble setpoint, and then slows to trickle feed rate.

Bucket Elevator

The bucket elevator is a compact, inexpensive way to deliver at very high rate to the weigh scale. The residual in the boot is very small, but a quick clean boot allows complete purging, if necessary.

Major Scale Hopper

The major weigh hopper is closed top, with an inspection port, an inlet isolation sleeve, and is vented to dust collection. The chisel bottom insures rapid and complete discharge to the high volume screw feeder. The feeder has a full port discharge gate to prevent the current batch from flushing out from the scale hopper. This hopper discharges at 1,200 to 2,000 lb/minute.

Bag Dump Station

The Applicon BD-20 bag dump station in stainless steel, has 20 cu.ft. (500 l) hopper to hold up to 1,000 lb. of minor ingredients dumped from 50 lb bags, or manually by scoop. It has an integral fan and filter bags that are pulsed clean, returning the dust to the current batch. A bag table and bag grate make cutting and dumping bags ergonomic and quick.

The hopper is vibrated & isolated, and fluidized to insure that all ingredients descend to the vacuum takeoff.

Vacuum Filter Receiver

Applicon high volume VFR and scale verifies the weight moved from the bag dump station.. This too has reverse pulse cleaning of the bags, to insure all ingredients stay with the current batch. Upon readiness, the VFR discharges via full port slide gate to the blender infeed screw. The major ingredient scale chases these minor ingredients from the infeed screw.

Vacuum Blower Package

This PD blower pulls high vacuum to dependably convey at high rate, across a wide range of ambient conditions and product flowability.

Blender Loading Screw

Applicon RTM charger is a screw feeder to charge the batch into the blender at up to 2,000 lb./minute. The feeder inserts into the blender, eliminating the typical slanted infeed chute, and thus reducing the headroom required. The major scale discharges last, thus purging the minors entirely from the feeder, and leaving a residual of only a few pounds of the majors.

The RTM charger is mounted on rails for retraction from the blender, for inspection and service of both the feeder and the mixer inlet.

Rotary Tumble Mixer

Applicon RTM, or Rotary In-line tumble blender, RILB-40 SS is a stainless rotary mixer with a working volume up to 40 cu.ft. For plant nutrients, this is approx. 2,400 lb. per batch, but for very dense materials such as abrasives, the mixer and drive will handle up to a 5,000 lb. batch.

The mixer flights continuously lift and tumble the batch, while also translating the ingredients axially both forward and back. This complex motion produces a uniform blend in 2 to 3 minutes, without segregation, continuing even as the blender is discharging. Including both the infeed and discharging times, this system can produce 7 to 8 batches per hour. FAST.

The cascading batch presents a very broad field of dry product to receive a fan of sprayed fluid. The mixer is readily retrofit with either drip or spray bars for fluid micronutrients that are unavailable as powders or granules.

|

Applications • Abrasives • Animal Feed • Breading • Castable refractories • Ceramic blends • Coated granules • Coated sands • Coffee • Grout & pre-mixes • Herbicides • Horticulture mixes • Metal powders • Minerals • Nutraceuticals • Plant nutrients • Refractory blends • Seed mixtures • Snack mixes • Tea leaf |

Filling station

The blender has a plug style discharge valve. When open, the blender will fully discharge in only 1.5 to 2 minutes. However, this plug valve can also throttle the flow, or can re-close and seal while the blender is rotating. The translucent Portabin allows filling by sight, but a high level interlock prevents overfilling. The Filling Station can also be equipped with a scale or FIBC weigh filler

The discharge plenum is vented to dust collection, and mates closely to the bin that is being filled, to handle the displaced air during filling. The Pbin is locked in position until filled, then is released.

Portable Bins

Using Portabins allows product packaging to be decoupled from the batching and blending. The Pbin receives up to two batches, and is replaced by an empty. The filled bin is forklifted to the bag filling system elsewhere in the plant. These bins can be either CVB or stainless “tote” style bins. The cone valve bin has a 20” diameter discharge with seal cone. When moved to the Packaging system, the cone valve allows mass flow extraction of the blended product, eliminating risk of segregation.

Gravity Roller Rails

Roller rails carry the portable bins through the Filling Station. The separate rails make a safe walkway to manually push the portabins into, and from, the filling station. Actuated stops, position sensors and interlocks insure the bin is properly positioned while the blender is discharging.

The roller ways are elevated to allow easy sweeping beneath.

Bag Packing (not shown)

Each portable bin, with 2,400 to 4,000 lb. of product, is carried to the dual spout bag filling system elsewhere in the plant. This decouples the batching and blending from finished product packaging. Click HERE to see packaging system.

One Vendor, One Builder

Applicon designs and builds batching, blending, handling, and packaging systems. One source of equipment, one responsible vendor.

We specialize in building systems for tight spaces and tight budgets.

|

Blender Charge Screw |