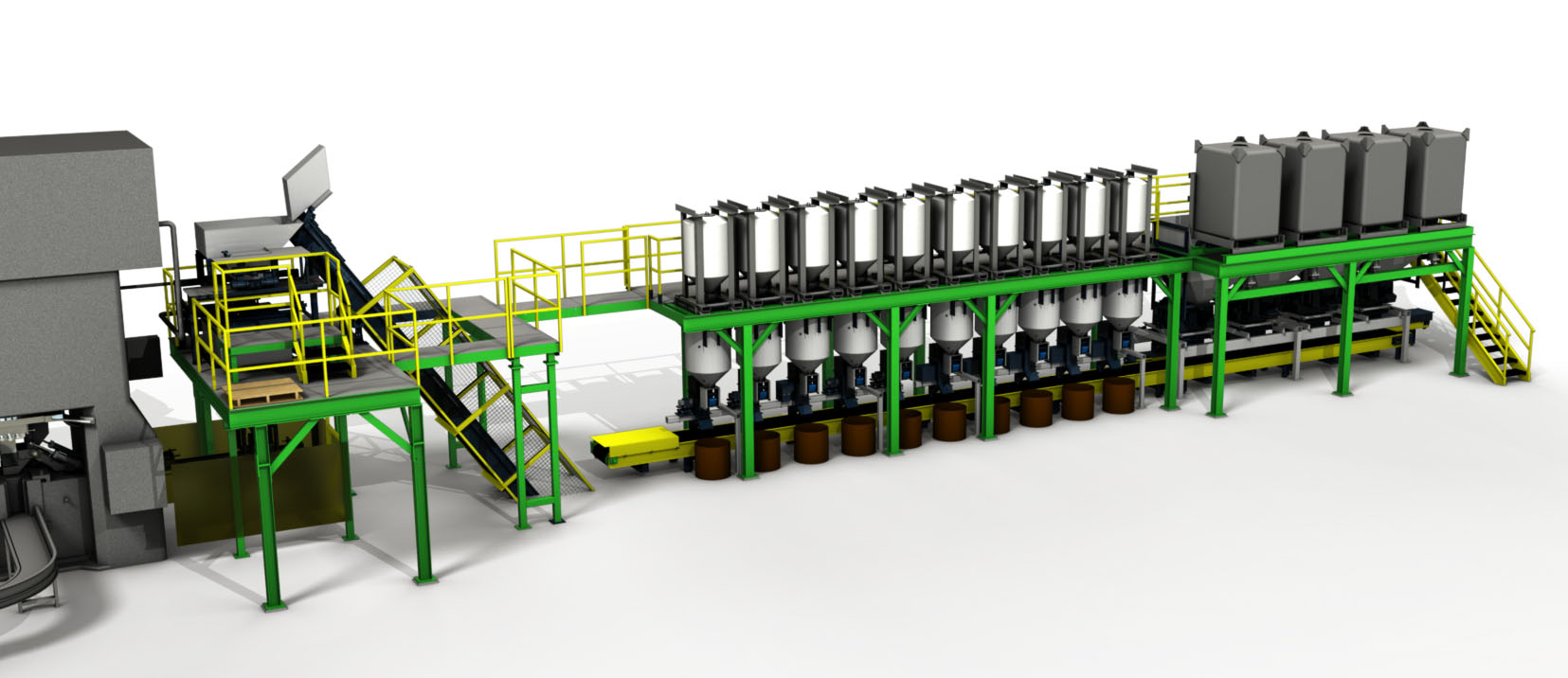

Applicon designed and built this linear batching system to serve a metals company to make alloy compacts (large briquettes) for building revert electrodes.

We identified these design goals for the system:

• Fit the system underneath the crane way used for electrode handling

• Reduce material handling to minimize forklift traffic

• Provide sufficient storage and consistent delivery of chips

• Dispense four major ingredients and up to ten alloying ingredients, to make a 150 lb batch

• Weigh each ingredient to within 0.5% of its requested weight

• Reject any single ingredient that is over weight

• Recover any rejected weighment for reuse

• Keep each weighed ingredient together with all others, of that batch

• Deliver each batch, without loss, and without co-mingling with the prior batch

• Blend the batch after adding a micro-ingredient, a fine powder

• Deliver the blended batch, with minimum segregation, to the briquetting press

• Charge the batch into the press die cavity

• Repeat those steps, every few minutes, two shifts per day, for 15 to 20 years

Linear Low

The limited overhead clearance required using a low profile linear system. Forklifts deliver large totes of the major ingredients, which discharge to the major holding bins. The various alloys were delivered in smaller portabins, having been filled at floor level with bags or drums of each alloying agent.

Making Time

Weighing fourteen ingredients successively was impossible both for time and accuracy. Applicon designed the system such that every ingredient was weighed simultaneously, each ingredient on a scale suitable for that alloy. Major ingredients were weighed in medium capacity scales; the minor ingredients were weighed in high precision scales with resolution to a few grams.

This simultaneous weighing creates time. Each ingredient has most of the batch cycle, allowing each feeder more time to creep up to the final weight. This virtually eliminates over/under weighments.

Making Elevation

Low linear batching systems usually require re-elevating, which is an opportunity to lose product and cross contaminate batches. Applicon solved this with a dual skip hoist. Each hoist bucket is designed to hold an entire batch without spillage, and each skip handles alternate batches; once again, making time, and regaining 5 meters of elevation.

Up high, the skips charge a rotary tumble mixer, which also then receives a few grams of powder from the micro-ingredient scale. After a few turns, the mixer dumps to the Press Die Filling System.

Marking Success

By considering all parameters, by careful design, and by robust construction, our system has been operating for 14 years (as of this writing).

Applicon builds multi-ingredient batching systems: • of all styles • for any number of ingredients • for any batch size • high accuracy, high frequency, or both

Call Applicon to solve your batching & dispensing needs.