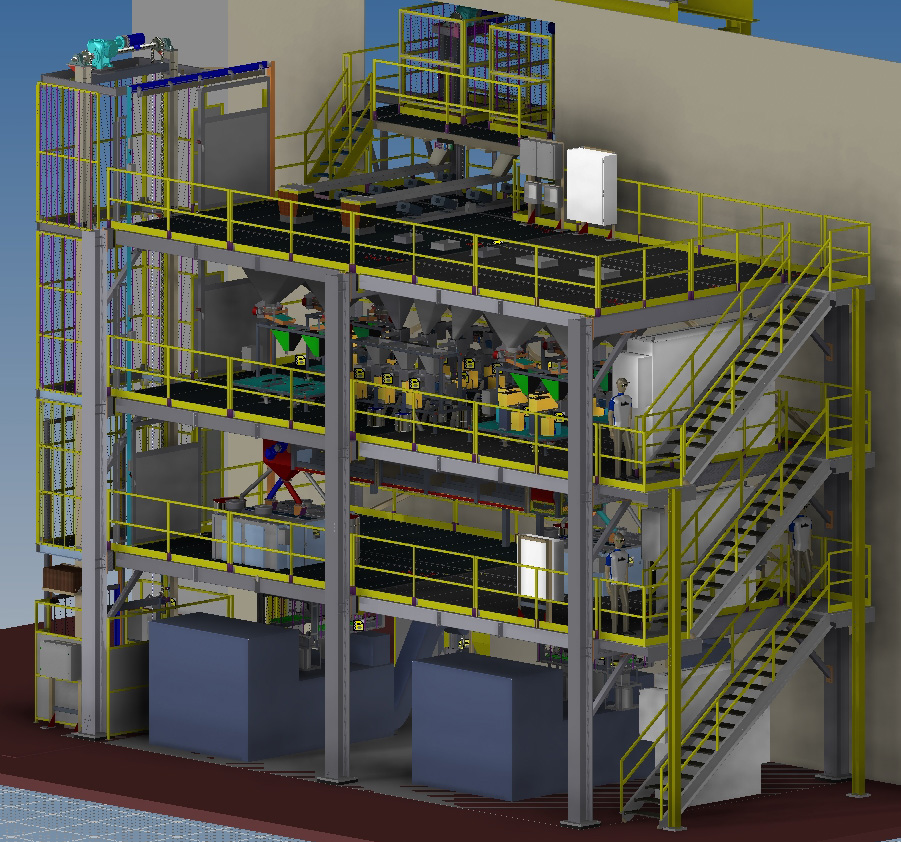

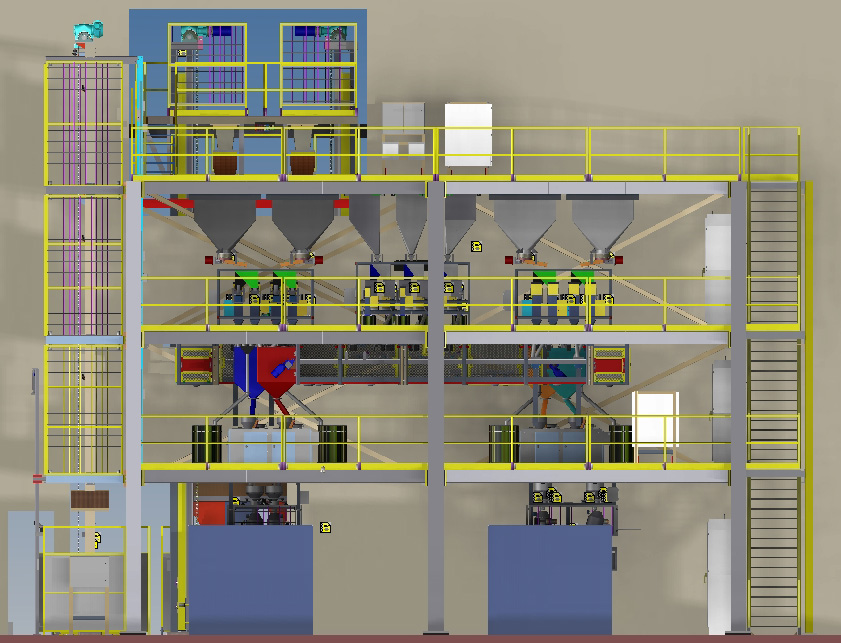

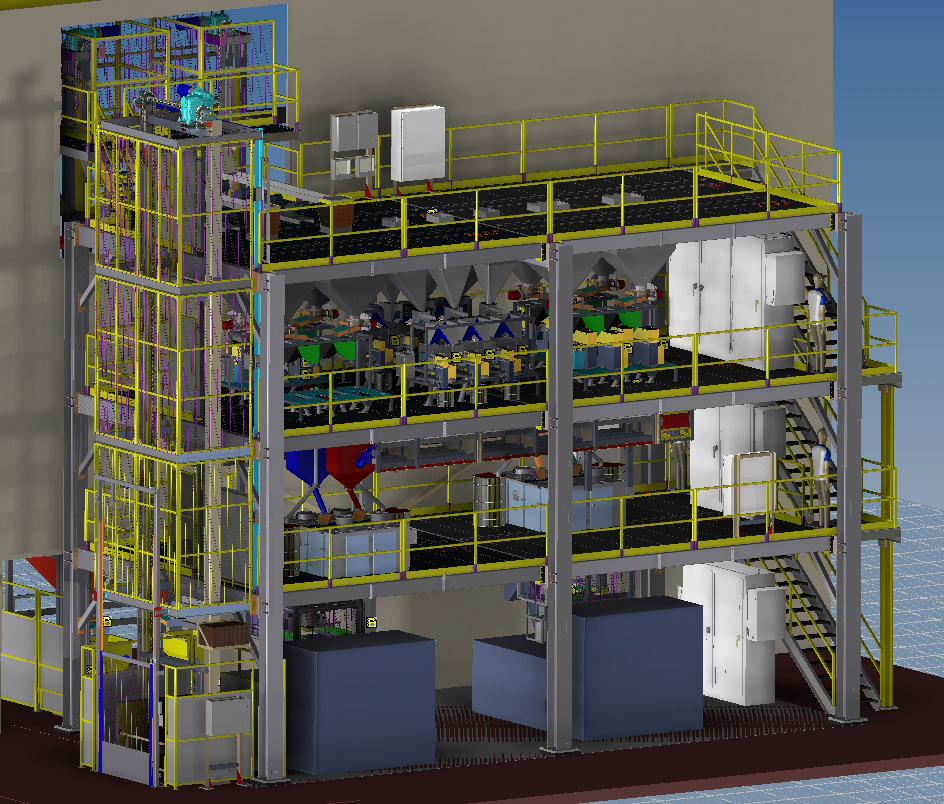

A North American manufacturer of non-ferrous products had used Applicon for two prior occasions to design and build multi-ingredient batching systems. Those systems had been in service for 12 years and 6 years respectively, when the customer contacted us for another system. The new system was to be relatively low tonnage, but much faster batching, and extremely high accuracy.

As with the two previous systems, this too had to operate within the shop, where vibration from heavy cranes and forklifts, and air currents from exterior doors, was normal.

We built the system in pre-populated modules, to shorten the time required for installation and system debugging. Each scale was equipped with vibration isolation, and the smaller scales also provided with enclosures to minimize perturbations from winds.

Two major ingredients were processed within the plant, and were delivered in bulk and dumped to holding bins. Those materials are metered to two 35 ft. vertical skips and conveyed to holding hoppers on the upper floor of the tower. Two lesser major ingredients arrive from outside vendors, and are dumped to 55 cu.ft. portable bins. These are elevated via a 2 ton capacity vertical reciprocating conveyor ( VRC ), then rolled and discharged to dedicated holding bins.

Minor ingredients are dumped to 10 cu.ft. portable bins, which also ascend via the VRC, and discharge each to their own holding bin. All of the bins are designed for complete discharge.

The several micro ingredients, some as small as 1 gram per batch, are manually filled into high precision feeders. These micro batches are dumped directly to the blenders, to avoid any loss in transit.

The system produces six blended batches per minute.

|

This processing system uses: • VRC lift for pbins & pallets • Vertical skip conveyors • Eight 10' x 20' deck modules • Two vibratory conveyors • Eight micro scales, < 1 gram • Twelve minor scales • Sixteen major scales • Zero loss horizontal conveyors • 55 cu.ft. portable bins • 7 cu.ft. sanitary portable bins |

|